White tea is renowned for its high quality, distinguished by its subtle and delicate flavor.

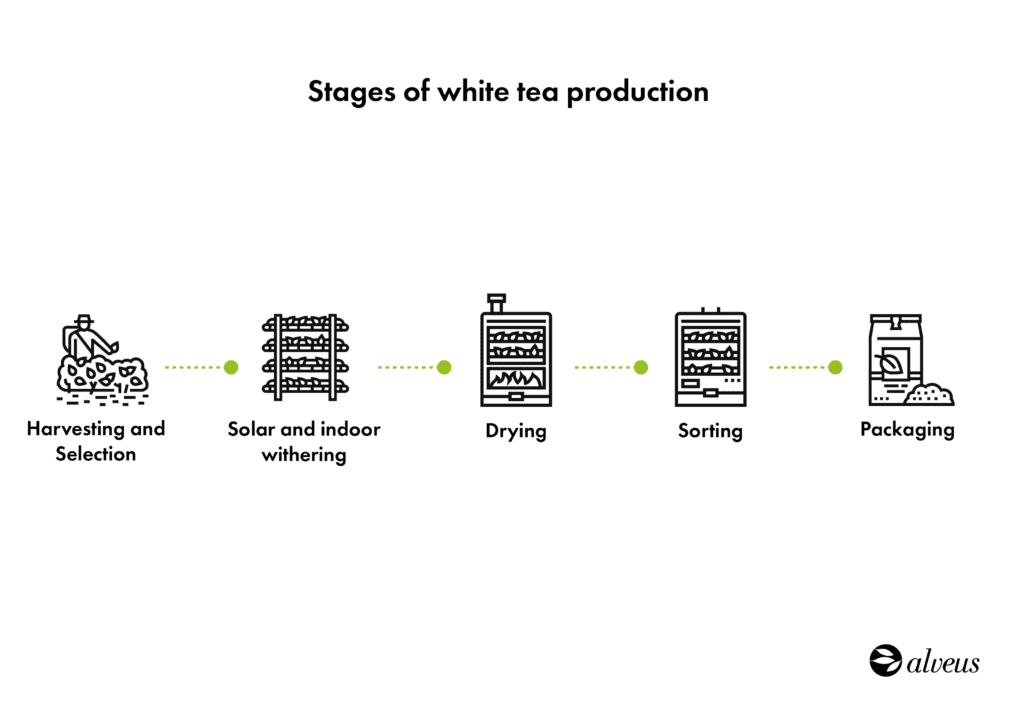

How is white tea obtained? Unlike other varieties, it involves a relatively simple process, except for its meticulous handpicking step, a challenge to meet the required quality standards.

Originating from the Fujian province of China, a region steeped in tea production history, white tea has long been synonymous with this area’s tea-making legacy.

The tradition of harvesting the youngest and most tender buds of the Da Bai tea plant (the cultivar primarily associated with white tea, known for its abundance of small velvety buds) has been passed on through generations.

White tea production entails meticulous selection and handling of tea leaves, coupled with precise control. In this article, we delve into the detailed stages of white tea creation, uncovering the challenges and techniques employed to ensure its exceptional quality.

First Phase: Meticulous Harvesting and Selection of Tea Leaves

The initial step in crafting white tea is the meticulous gathering and selection of tea leaves. It’s crucial to adhere to various requirements during this phase to ensure the chosen leaves are of the highest quality.

Here, we outline the key requisites of this stage:

Selection of the youngest and most tender leaves

Priority is given to the youngest shoots and the first leaves of the tea plant known as “silver needles”.

Hand Harvesting

Unlike other types of tea that can be harvested using machinery, white tea is hand-picked, which is also reflected in its price. Expert harvesters hand-select the most suitable leaves for white tea production.

Ideal Harvest Season in Spring

The harvest season for white tea varies by region but generally occurs during spring when the leaves are most tender and contain high levels of aromatic compounds. During this season, the weather conditions are usually ideal, with moderate temperatures and low humidity, contributing to the tea’s final quality.

Sunny Weather Conditions

Harvesting on sunny and dry days is preferred as excessive moisture can negatively affect leaf quality and promote mold development.

Damage-Free Harvesting Technique

Tea harvesters employ specific techniques to wisely gather the leaves, causing minimal damage. This may involve using special scissors or simply delicately pinching the leaves with fingers to avoid unnecessary harm to the plant.

Second Phase: Solar Withering of the Leaves

After harvesting, the leaves undergo the process of solar withering.

During solar withering, which usually occurs in spring and autumn, freshly harvested leaves are placed on bamboo mats in a dry area and exposed to direct sunlight. This process is carried out during times of lower solar intensity to avoid damaging the delicate leaf structure. Thus, the leaves partially dry out and lose some natural moisture.

The duration of the process varies depending on the weather conditions and the type of white tea being produced, but it generally lasts from a few hours to a full day.

During this time, the leaves undergo minimal oxidation. Additionally, as they lose moisture and release volatile compounds, they develop their delicate and natural aromas.

Controlling moisture is crucial to prevent the leaves from overdrying or becoming brittle. In summary, solar withering is a step that lays the foundation for the distinctive character and the exceptional quality of white tea.

Third Phase: Indoor Withering

In most white tea production factories, the leaves are moved to the indoor withering process, where the moisture removal stage is completed.

This step is carried out in a controlled environment, specifically designed to maintain optimal temperature and humidity, so the leaves wither gradually, preserving their flavor and aroma.

The leaves are placed back on mats inside a prepared room, where fans promote air circulation. This flow helps accelerate the evaporation of moisture from the leaves and contributes to uniform withering.

This process can take several hours, or even days, depending on factors such as the initial moisture content of the leaves and the producer’s preferences regarding the desired flavor profile for white tea.

Fourth Phase: Drying of Tea Leaves

The drying process in white tea production aims to reduce the moisture content of the leaves and stop their oxidation completely.

To achieve this, different manufacturing facilities combine traditional methods with modern techniques, always striving to maintain the integrity of the leaves in perfect conditions without causing breakage that could affect the final price of the tea.

The most traditional drying method is through charcoal, where the leaves are exposed to the heat of charcoal, acquiring a characteristic aroma. This technique has endured since the ancient Chinese Ming and Qing dynasties.

On the other hand, modern technology has introduced new drying methods that optimize the process and ensure consistent results. This is the case with electric drying machines, used in contemporary white tea production. These devices guarantee precise temperature and humidity control, ensuring a uniform evaporation and an optimal tea quality.

These approaches, both traditional and modern, have the ultimate goal of reaching a specific moisture level in the tea leaves, typically around 5%-6% moisture, which is ideal for long-term storage. This meticulous drying process not only preserves the freshness and integrity of the leaves but also enhances their characteristic flavor and aroma.

Fifth Phase: Sorting of White Tea

Once the leaves have undergone the drying process, they are ready for consumption. It’s time to carefully sort them to ensure uniformity in terms of the size and appearance of the final product.

This step separates the high-quality leaves from those of lower quality so that only the best ones reach the consumer, meeting the desired quality standards.

The sorting process is often done manually, with trained teams meticulously selecting the leaves. Using their fingers or specialized tweezers, these sorters separate the higher-value leaves, such as silver needles and the tenderest buds, from the lower-quality leaves.

This process can be carried out in the same production factory or in specialized facilities managed by traders with a deep understanding of consumer preferences.

Final Phase: Packaging of White Tea

Once all production and sorting stages are completed, the tea is now ready to be packaged and delivered to wholesalers and industry professionals worldwide.

In this final phase, the tea is carefully packaged to preserve its freshness, aroma, and characteristic flavor. Depending on the manufacturer’s and consumer’s preferences, white tea can be packaged in various formats, from vacuum-sealed bags to tea tins.

Each final package of white tea is designed to ensure it reaches its destination in optimal conditions, ready to be enjoyed.

Conclusion

In summary, the white tea process is a balance between tradition and modern technology. From the meticulous selection of leaves to careful drying and packaging, each step is crucial to ensuring the quality and consistency of the final product.

White tea remains a variety that is characterized by its premium quality in the world of tea. Therefore, understanding in depth how white tea is made not only enriches our understanding of this beverage but also provides us with the necessary tools to accurately promote and sell white tea on the market with confidence.