Black tea, originating from China, is one of the most consumed varieties of tea worldwide. To understand its distinctive character and intense, astringent, and robust flavor, it is essential to know all the phases of its manufacturing process.

As a tea industry professional, firsthand knowledge of how black tea is produced will help you to better understand its quality and unique characteristics. That’s why we invite you to discover its fascinating production process, from the harvesting of the leaves to their transformation into this exquisite beverage.

Origin and Cultivation

The production process of black tea begins in tea plantations, where the leaves of Camellia sinensis, the tea plant, are carefully cultivated. These plantations are found in various regions of the world, from the mountain slopes of China and India to the hills of Sri Lanka and Africa.

Tea leaves are harvested by hand or using specific machinery. The quality of black tea is closely linked to the timing of the harvest and the skills of the picker in selecting the most suitable leaves.

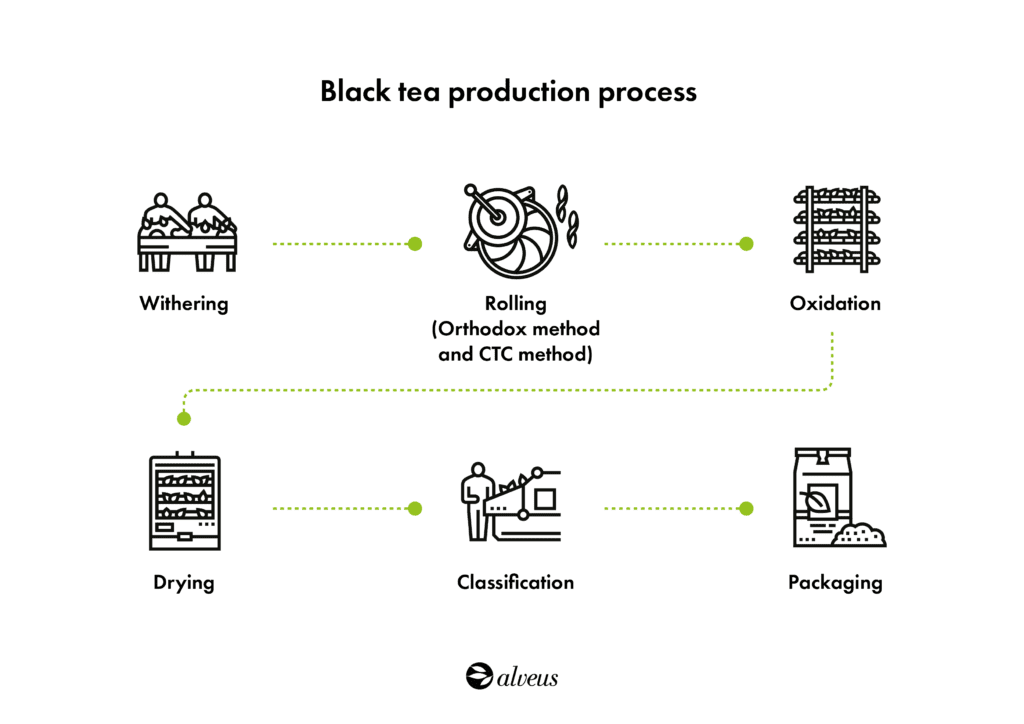

Black tea production stages

The manufacturing process of black tea requires spacious and multifunctional facilities due to the number of rooms needed for each stage.

Once the harvest is received, and before starting the black tea production process, an expert thoroughly inspects the leaves to confirm their quality, making sure that the harvest meets the required standards.

Withering

The black tea manufacturing process begins with the withering of freshly harvested leaves, a step that involves removing moisture from the leaf. For this, leaves are spread out on a surface, where they are exposed to air, or gentle heat is applied to remove this surface moisture.

Additionally, during this stage, a series of biochemical reactions are triggered that will influence the final flavor and aroma of the black tea, as proteins begin to convert into amino acids. This makes withering a key step as it will determine the final flavor and aroma of the tea.

Rolling

Once the leaves are withered, they are moved to this second rolling phase, in which they undergo a twisting process aimed at breaking the leaf cells and releasing the essential elements that will flavor the tea.

This process can be carried out using different techniques and methods, with the most common being orthodox rolling and CTC (Crush, Tear, Curl) methods.

Orthodox rolling method

A traditional slow rolling technique that can be done manually or with the help of specific machinery, such as cylindrical rolling boards or rotor vanes.

This method allows the production of whole and broken leaves, which are then sorted and graded according to their size and quality. Although it requires more attention than other methods and considerable skills from workers, the orthodox method is valued for its ability to preserve leaf integrity and produce high-quality teas with distinctive flavor profiles.

CTC (Crush, Tear, Curl) rolling method

This technique used in black tea processing, employs rollers with sharp teeth that rotate in opposite directions to crush the tea into smaller and more uniform particles.

The origin of the CTC method dates back to the 1930s and was created by William McKercher, driven by the increasing demand for tea bags and the need to increase efficiency in production.

Although this technique is criticized for being a deviation from traditional practices, its popularity has grown, especially in regions where strong and intensely colored infusions are preferred, such as in India and Pakistan, where tea is commonly consumed with milk.

Oxidation

Oxidation in the black tea process is crucial as it will define the tea’s character.

During this process, enzymes contained in the leaves react with polyphenols in the presence of oxygen, generating compounds that define the color and flavor of the tea.

In this phase, the leaf undergoes a visible transformation, changing from a green tone to a coppery or even brown tone. This is due to the biochemical change in the leaf, converting polyphenols into theaflavins (TFs), which contribute to brightness, and thearubigins (TRs), which provide strength and color to the finished product.

The tea manufacturer must be an expert in maintaining a balance between TF and TR, adapting to market preferences. If their potential market prefers lighter black teas, the leaves will undergo a shorter oxidation process: if their customers prefer a fuller, more intense tea, the leaves will undergo a longer oxidation process.

Temperature and room humidity also influence the oxidation process, requiring the manufacturer to be attentive an make adjustments accordingly. Once the optimal point of oxidation is reached, it is crucial to stop the process and stabilize the tea to preserve its quality and desired characteristics.

Drying

Once the leaves have reached the optimal level of oxidation, they undergo the drying process to stop the enzymatic reactions in the leaf and reduce moisture.

The drying stage in black tea production is essential to ensure the quality of the final product. It must be carried out at controlled temperatures (within a range of 80 to 130 °C), ensuring that the leaves reach their optimal dryness without suffering damage, to preserve the flavor and aroma of the tea.

Careful and controlled drying is essential to avoid bitter flavors and maintaining the integrity of the tea leaves.

Classification

In the black tea process and its production, classification is carried out by experts who meticulously separate the leaves according to their size, shape, and quality. This ensures that the production is as uniform as possible and meets quality standards.

The leaves are classified into different categories, ranging from whole leaves to smaller fragments, thus determining the grade and quality of the tea. Additionally, this stage may also include the removal of impurities or unwanted materials that may have remained on the leaves during the production process.

Packaging

Finally, the sorted tea is packaged in containers designed to maintain its freshness and flavor. Whether in boxes or vacuum-sealed bags, the packaging of black tea ensures that it reaches the distributors in optimal conditions.

In summary, the production of this type of tea is a complex process that combines ancient craftsmanship with innovative techniques to produce one of the most loved beverages worldwide. Each phase of the process, from withering to packaging, is essential to ensure the quality and exceptional flavor of black tea.

Conclusion

The black tea production process is a fascinating journey that blends tradition with science, skills, and patience. From the tender leaves in the plantation to the steaming cup in the hands of your customers, each phase contributes to creating a unique experience. Black tea is not just a beverage; it is a legacy to human mastery and the richness of nature, distilled into a cup that transcends time and borders.