Dark tea is a unique variety quite different from other types of tea due to its fermentation process, which develops its peculiar flavour and aroma. Despite its name suggesting a reddish hue, its colour can range from deep amber to intense red or brown.

This type of tea originates in China, where it has been cultivated and consumed for centuries. Based on common knowledge its production dates back to the 16th century in the Hunan Province, particularly in the counties of Anhua, Yiqang, and Linxing.

Although there are different sub-varieties of Dark tea, Pu-erh tea is the most popular, traditionally marketed, and consumed. Consequently, Dark tea is often directly associated with Pu-erh tea.

Pu-erh tea is named after the region where it is harvested, Pu’er County, located in the southern part of Yunnan Province in China, in the Ying-Shen region (currently Simao and Xishuangbanna).

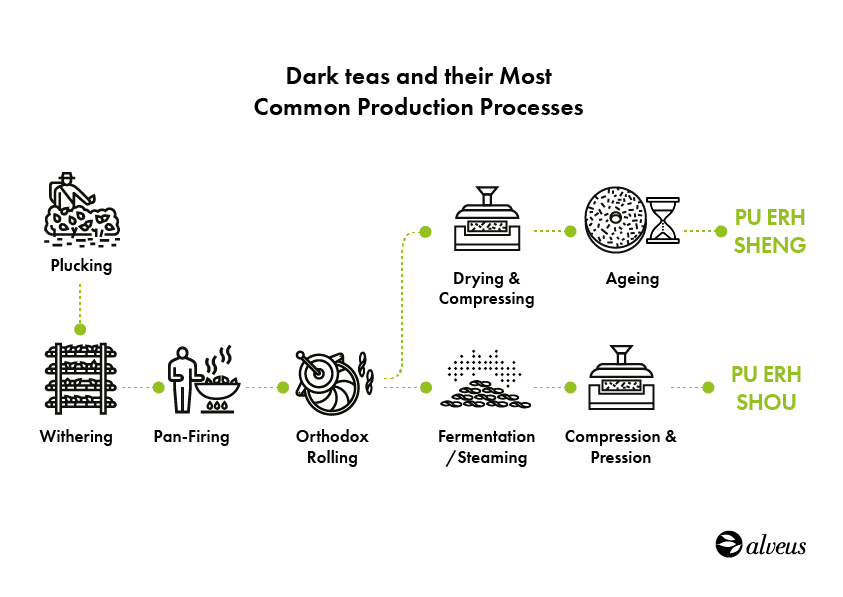

In this article, we will explain the production process of Pu-erh tea, while also mentioning the production methods of other interesting varieties.

Pu-erh Tea Production Process

Pu-erh tea undergoes microbial fermentation rather than oxidation, classifying it as fermented tea, similar to other Dark teas. This characteristic imparts a distinctive flavour and beneficial properties.

Despite following different production paths, both Sheng Pu-erh and Shou Pu-erh undergo a maturation or ageing process. Additionally, their production uses tea leaves from the same plant as other teas, with a particularity: Pu-erh tea (especially Shou or ripe) tends to privilege the harvesting of more mature leaves.

Stages of Production for Sheng Pu-Erh (Raw)

1. Harvesting and Collecting Tea Leaves

The production of raw Pu-erh tea begins with the harvesting of both young and mature leaves from the oldest tea trees, which adds a notable complexity to the flavour of this tea.

2. Withering the Leaves

Subsequently, the leaves undergo a withering process. They are carefully placed on bamboo or cloth mats to lose part of their natural moisture.

Ideally, this process is done outdoors, using sunlight to accelerate withering. However, if weather conditions do not allow it, it can also be performed indoors.

3. Fixing

After withering, the next crucial step in Sheng Pu-erh tea production is fixing. This process, known as “sha qing” or “kill the green,” involves heating the withered leaves in special pans.

Fixing is essential to stop leaf oxidation and preserve fresh, natural green colour. During this stage, the leaves acquire a distinctive aroma, and the enzymes responsible for oxidation are deactivated.

4. Rolling

Once fixed, the leaves move to a rolling phase, usually following the orthodox method. The leaves are rolled, manually or mechanically, to break the cells and release the internal juices that will impart flavour to the tea. This rolling process helps initiate fermentation and controlled oxidation of the leaves, influencing the tea’s flavour.

The way the leaves are rolled can vary based on traditional or modern production practices, as well as on the producer’s preference. Proper rolling is crucial to ensure an even distribution of aromatic compounds and balanced fermentation throughout the batch of tea.

5. Drying

After rolling, the leaves enter the drying phase, where the remaining moisture is removed to stabilize the tea and prepare it for long-term storage. During this process, the leaves are exposed to hot air or sunlight to evaporate the excess water, ensuring the preservation of aromatic and nutritional compounds.

Careful drying is essential to maintain the freshness and quality of Sheng Pu-erh tea, as well as its ageing potential.

6. Compression

Once the leaves have been dried, the next step is compression, where they are carefully pressed into compact cakes or bricks. This technique not only facilitates storage and transportation but also plays a crucial role in the development of flavour and quality over time.

Compression is performed with precision to ensure a uniform shape and adequate density, allowing for gradual and balanced fermentation, resulting in high-quality, exceptionally flavoured Sheng Pu-erh tea.

7. Aging and Fermentation

The aging of raw Pu-erh tea involves a natural, slow, and controlled fermentation process that occurs while storing the pressed “cakes” in warm and humid environments.

The Dark tea leaves are exposed to specific temperature and humidity conditions, allowing bacteria and enzymes to break down the tea components. Over time this process gradually transforms the raw, astringent flavours of the tea into smoother, sweeter, floral, and earthy notes.

The slow, natural ageing of Sheng Pu-erh is a delicate process that requires patience and care to achieve optimal results, which is reflected in its final price. Nevertheless, this distinctive and unique character is highly appreciated by tea enthusiasts.

Production Stages of Pu-Erh Shou Tea, Cooked or Ripe

The production stages for ripe or cooked Pu-erh tea, also known as Shou Pu-erh, are almost identical to the production of raw Pu-erh up until the maocha stage and after the drying of the tea leaves. However, after drying, the tea undergoes a fermentation before the compression.

Therefore, Shou Pu-erh production process follows these steps:

- Harvesting the tea leaves.

- Withering.

- Fixing (kill the green) to obtain maocha.

- Rolling.

5. Pu-Erh Shou: The Fermentation

The fermentation of Shou Pu-erh, known in Chinese as Wo Dui and in English as Wet Piling, involves storing the tea leaves in large piles for extended periods, often six weeks or several months.

During this process, the leaves are periodically moistened to promote increased microbial activity, essential for accelerated fermentation. The bacteria and fungi present in the environment and on the tea leaves interact with the chemical compounds of the leaves, transforming them and developing the unique flavours of Shou Pu-erh. This process also helps reduce the tea’s astringency and bitterness.

Fermentation is a crucial aspect in the production of Pu-Erh Shou, as it develops the unique earthy aroma and complex flavours that differentiate this type of cooked Pu-Erh tea.

The microbial activity during piling transforms the natural compounds present in the tea leaves, creating a balanced flavour with distinctive notes.

6. Pu-Erh Shou: Steaming

During the steaming process of cooked Pu-Erh tea, the freshly fermented leaves are exposed to steam to stop the enzymatic activity and set the flavours and aromas developed during fermentation. The hot steam penetrates the leaves, softening and making them more flexible. This facilitates their subsequent compression into various shapes, such as cakes or compacted bricks.

Steaming also helps remove any remaining moisture from the leaves and contributes to the stabilisation of the tea, ensuring its quality and freshness over time. Additionally, this process enhances the tea’s aromatic and flavour qualities, imparting depth and smoothness.

7. Pu-Erh Shou: Compression and Pressing

Similar to raw Pu-Erh, this seventh stage of the ripe Pu-Erh production involves compressing and pressing the leaves into shapes such as cakes or touchas.

This method facilitates the storage and commercialisation of this type of tea. Moreover, during this process, the preservation of the natural flavours and aromas of the tea is promoted. After this compression stage, only proper packaging remains before the tea is ready for sale.

In summary, Pu-Erh Sheng and Pu-Erh Shou are two varieties of Dark tea characterized by their intriguing production process, each with its peculiarities and key characteristics of taste, aroma, and colour. While Sheng stands out for its natural fermentation and gradual ageing, offering subtle and complex flavours, Shou is differentiated by its accelerated fermentation, resulting in an earthy and smooth taste.

Both types of Pu-Erh have a unique place in the world of tea, appreciated for their history and wide range of flavours.

Other Types of Dark teas and Their Production Process

Fu Tea or Brick Tea

Fu tea, also known as brick tea, stands out as a unique variety within the realm of Dark teas, boasting a production process that sets it apart from others like Pu-Erh.

One of Fu tea’s most remarkable characteristics is its smooth and refined taste, which develops through a controlled fermentation process and an additional fermentation known as Fahua.

During the production process of Fu tea, the leaves undergo an initial heat treatment to stop oxidation before being stacked to encourage fermentation. The stacking, together with the application of a special solution onto the leaves, contributes to the Fahua fermentation, which is crucial for the development of the tea’s flavour and aroma.

A distinguishing feature of Fu tea is the presence of a golden mould known as Jin Hua (Golden Flowers), which forms during the fermentation process and serves as an indicator of the tea’s quality. Hand-produced Fu tea tends to have a greater abundance of Jin Hua compared to machine-produced tea, resulting in a smoother and more refined taste in the cup.

In summary, Fu tea is valued for its smooth and refined flavour, along with its unique production process involving Fahua fermentation. The presence of Jin Hua and its properties make it a popular choice among tea enthusiasts worldwide.

Closing thoughts on fermented tea production

In conclusion, Dark tea, with its multiple sub-varieties and diverse production processes, constitutes a significant share of the tea market. Particularly, Pu-Erh tea in its Sheng and Shou varieties, with their complex fermentation and ageing processes, and their wide range of flavours, are intriguing options for both consumers and tea professionals.

The diversity of flavours, ranging from earthy to sweet and floral notes, provides a unique sensory experience. Moreover, its ability to improve with time makes it an attractive investment for those seeking premium-quality teas.

In summary, Dark tea represents an important and valuable part of the tea world, offering a wide range of options to satisfy even the most discerning palates.