What Makes Green Tea So Special? To answer this question, we must look into how it’s made, unveiling the mysteries behind this ancient beverage.

Green tea, originating from China over 4000 years ago, has become a beverage consumed by two-thirds of the world’s population. It stands out for its freshness, flavor, and beneficial properties in our daily lives.

This makes it the favorite choice among tea connoisseurs and industry professionals. As a professional, understanding the steps involved in green tea production will help you provide a quality experience to your customers, and convey precise and detailed knowledge about this type of tea.

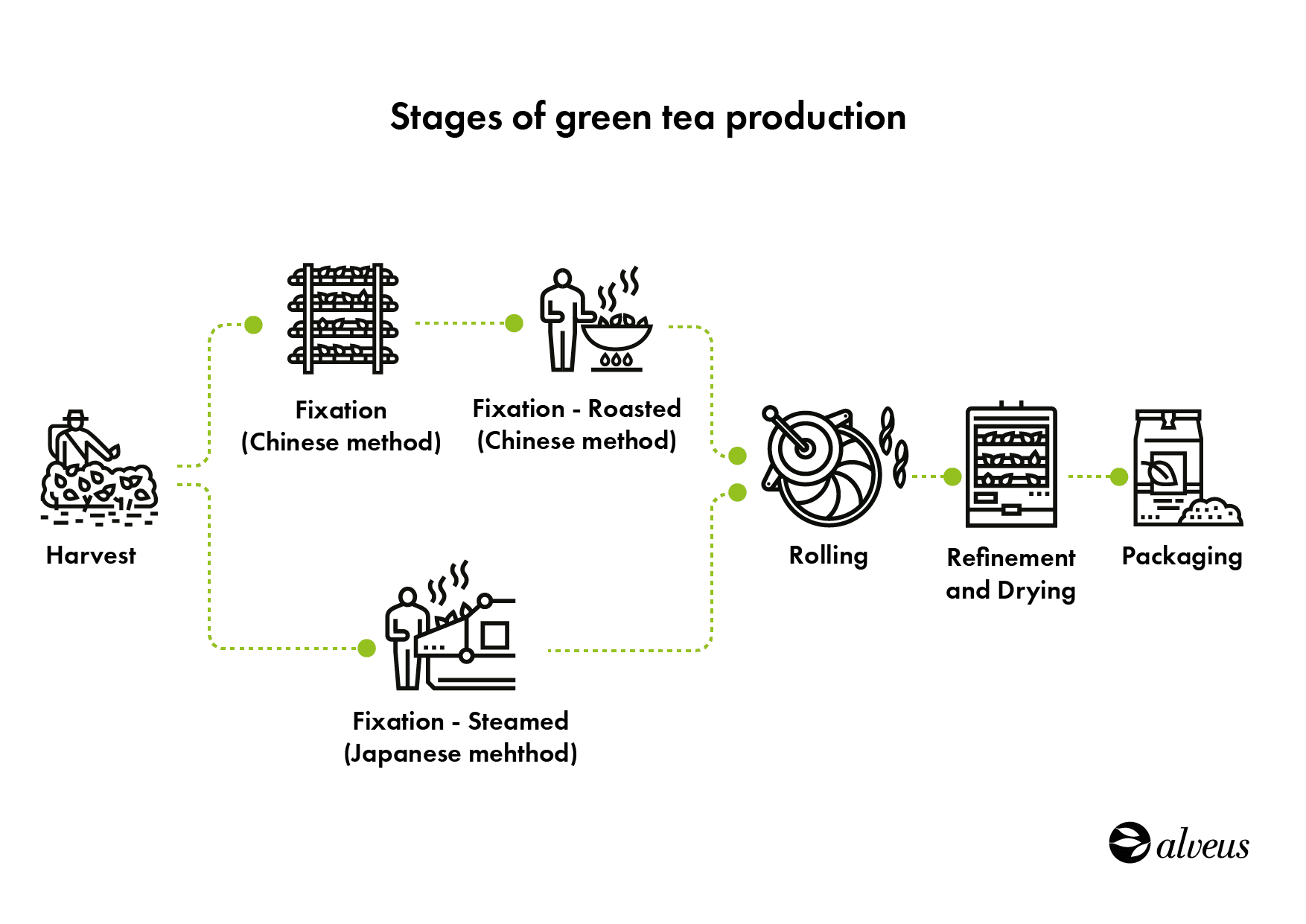

Stages of Green Tea Production

In the green tea production process, the main difference that defines its characteristic bright color and flavor compared to other teas like black tea, lies in the minimal oxidation experienced by the tea leaves.

This is achieved through carefully controlled phases that preserve the natural freshness of the leaves and maintain their antioxidant properties and delicate, refreshing flavor.

Variations in Green Tea Processing

Before looking into how green tea is produced, it’s important to note that there are various methods employed, each one determining the different stages of the process.

The two most common methods of green tea processing are:

– The Chinese-style method – roasted green tea.

– The traditional Japanese method – steam green tea (or Sencha).

The first difference we encounter between these methods is how leaves are withered. While in the Chinese method withering is a fundamental stage, in the Japanese method, the leaves go directly to the step of fixation by steam, bypassing withering.

Now, we will explain in detail the stages of the process of the production of green tea, that contribute to maintaining the distinctive character of this infusion.

Harvest

The green tea production process begins with the harvesting of tea leaves, usually done by hand to ensure the selection of the youngest and freshest leaves. Once harvested, the leaves are quickly transported to the tea factory for processing.

The primary tea plantations and green tea factories are mainly located in countries with a long tradition of tea production, such as China, Japan, India, and Sri Lanka. These countries have ideal climates and geographical conditions for the cultivation of the Camellia sinensis tea plant, as well as accumulated expertise in green tea cultivation and processing techniques.

For example, in China, the regions of Zhejiang, Fujian, and Yunnan are known for their green tea plantations, while in Japan, the prefectures of Shizuoka, Kyoto, and Uji are some of the significant production areas.

Withering (only in the Chinese processing method or roasted green tea)

In the Chinese processing method, tea leaves undergo a withering process, where they are left to rest on special trays to reduce their moisture content.

This step helps prepare the leaves by removing their moisture, thus preventing the leaves from burning during the subsequent roasting process.

Fixation

Fixation is the crucial phase in the green tea process. This stage focuses on preventing oxidation and maintaining the freshness of the leaves.

Fixation involves quickly heating the leaves, either by steaming (Japanese method) or direct exposure to heat in a hot pan (Chinese method). This process deactivates the enzymes responsible for oxidation, thereby preserving the characteristic bright green color and natural flavors of the leaves.

Once fixed, the leaves are rapidly cooled to prevent further oxidation and excessive toasting, ensuring the desired quality and flavor are preserved.

As mentioned earlier, green teas are divided into two main categories based on this fixation stage: roasted green teas and steamed green teas.

Next, we will explain in detail how the leaf oxidation is stopped in each of the methods.

Fixation of ROASTED GREEN TEA (Chinese-style method)

In roasted teas, also known as teas processed in the Chinese style or “sha qing,” the leaves undergo a fixation process by direct exposure to dry heat in a pan or hot container.

During this process, the leaves are tossed and pressed against the sides of the hot container, giving them a characteristic flavor with toasted notes and a slight golden color in the infusion.

Fixation of STEAMED GREEN TEA (Sencha or traditional Japanese method)

On the other hand, steamed teas, traditional in Japan, undergo a fixation process by exposure to steam. This method preserves the freshness and nature of the leaves, resulting in a more vegetal flavor and a vibrant green infusion.

This fixation is carried out for the production of famous green teas such as Sencha and Gyokuro.

Rolling

After fixation, the green tea leaves are carefully rolled to release their characteristic aromas and flavors.

This rolling process in green tea production, which can be done by hand or mechanically, helps enhancing the quality and texture of the leaves, creating an exceptional tasting experience.

Refinement and Drying

Once rolled, the green tea leaves are classified according to their size, quality, and flavor, removing stems and impurities.

Afterwards, they are carefully dried to remove the remaining moisture and preserve their freshness and flavor, prolonging their shelf life. Drying can be done by exposure to the sun or in special dryers, depending on the producer’s preferences and local weather conditions.

Packaging

As the final step in the green tea production process, the tea leaves are packaged in airtight bags or cans to preserve the product in proper conditions. This final step of the green tea production process ensures that each cup of green tea will be an experience full of flavor, aroma, and vitality.

Conclusion

In essence, the production of green tea is characterized by its careful process, which limits the oxidation of the leaves to preserve their natural freshness and flavor. From withering to drying, each stage is crucial to ensure the quality and uniqueness of green tea.

For tea industry professionals, understanding the production process and its techniques is essential to enable offering quality products and meeting the demands of the most demanding consumers.