The production process of yellow tea stands out for its uniqueness, requiring a deep technical understanding, exceptional craftsmanship, and more labor-intensive work compared to other tea varieties.

Yellow tea is one of the least common and least understood varieties in the tea industry, representing just 1% of the world’s tea production. This low percentage is largely due to its extremely unique and laborious production process, which takes up to three days to complete, resulting in limited produced quantities.

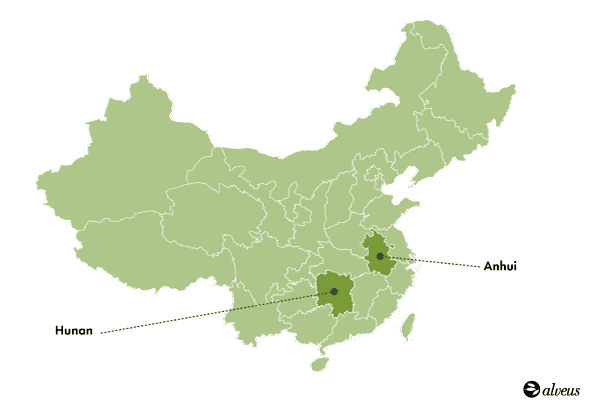

Almost exclusively produced in China, mainly in the provinces of Anhui and Hunan, this tea shares some similarities in its production process with green tea. However, it differs from it by having an additional step contributing to its characteristic flavor profile.

In this article, we will explore the key stages of yellow tea production, highlighting the specific techniques used by tea masters to create this distinctive and cherished beverage.

Tea Harvesting

As for other varieties, the yellow tea production process begins with its harvest. Harvesting usually occurs in March, a decisive time when the tea plant’s leaves and buds are at their optimum growing phase.

At this stage, experienced pickers meticulously select fresh and tender leaves, ensuring each bud has reached its ideal ripeness. This delicate operation guarantees the maximum quality and freshness of yellow tea, capturing its distinctive aroma and flavor.

Withering in the Sun

Once harvested, the tea leaves undergo a controlled withering process through exposure to the sun. During this crucial phase, the leaves absorb sunlight, triggering a series of internal biochemical reactions.

This withering process is essential to prepare the leaves for the next stage of the production process, known as fixation.

Tea producers carefully control the duration and intensity of withering to ensure the quality and consistency of the final product.

Fixation

Fixation, like in green tea manufacturing, is a fundamental phase in the yellow tea production process. In this phase, the withered leaves are submitted to high temperatures to stop their oxidation, deactivating the enzymes responsible for it.

In the case of yellow tea, fixation is carried out through the Chinese method of sha qing fixation, also known as pan-firing. This step, which requires precision and care, is important to preserve the natural flavors and aromas of the leaves, thus setting the base for the distinctive flavor profile of yellow tea.

It is important to note that, in most cases, producers usually perform this task with care and precision, manipulating the leaves by hand to ensure even heat distribution and proper fixation.

In some cases, after this fixation phase, the tea leaves are exposed to steam to promote their next semi-fermentation step. However, whether this production phase is carried out or not, depends on the duration of withering time that the tea has undergone.

Rolling

In some cases, after this fixation phase, the tea leaves are exposed to steam to promote their next semi-fermentation step. However, whether this production phase is carried out or not, depends on the duration of withering time that the tea has undergone.

Non-enzymatic Fermentation

During this process, the leaves are piled up and covered with the so-called “Cow Skin Paper”. This is a kind of leather material used to maintain proper humidity and temperature creating a conducive environment for the leaves to sweat, resulting in semi-fermentation or non-enzymatic fermentation.

Sweating contributes to developing the characteristic flavors and aromas of yellow tea, as well as its smoothness and distinctive sweetness. This process, known as “men huan” in China, allows flavors to intensify and concentrate, creating a unique sensory experience.

This procedure is repeated several times, often for hours each time, allowing the tea to reach its desired fermentation point. It can extend over several days until reaching the desired quality and flavor.

Drying

After going through the previous stages, the tea leaves undergo a meticulous drying process divided into small batches.

This step is essential to preserve the freshness and quality of the tea. Proper drying ensures that the leaves do not undergo over-oxidation, which could compromise their flavor and aroma.

Additionally, it contributes to maintaining the integrity of the tea, ensuring an optimal sensory experience for those who will enjoy it. This careful drying process is carried out with the utmost precision to achieve a final product of high quality and consistency.

Grading and Packaging

After completing the processing stages, the tea undergoes a grading process to ensure its quality and uniformity.

In this process, the leaves are selected and separated according to size, shape, and quality. This ensures that each tea batch maintains the desired quality standards and consistency in its flavor and aroma.

Once graded, the tea is carefully packaged for distribution. Packaging is carried out in small batches, due to the attention required in the process, to preserve the freshness and quality of the tea during storage and transportation.

Appropriate packaging materials are used to protect the tea from moisture, light, and air, all elements that could affect its flavor and freshness. This ensures that the tea arrives in perfect condition, ready to be enjoyed at its best.

Yellow Tea is synonymous with Exclusivity

If you want to offer incredible quality and exclusivity, we present you Alveus’ exclusive yellow tea, which stands out for its high antioxidant content and rare uniqueness.

Conclusion

The uniqueness of the production process, coupled with a limited available supply that is way less than the market demand, makes yellow tea a precious rarity desired by those seeking an unprecedented experience.

In summary, the production process of yellow tea is a combination of technical skill, artisanal expertise, and meticulous care. For tea industry professionals, understanding these stages and techniques is key to appreciating and conveying the exclusivity of this yellow tea variety to their customers.